BIN & SILO MAINTENANCE PROGRAMS

Preventative maintenance can be compared to going to a doctor or dentist for a check-up. You know that it is the smart thing to do. Problems can be spotted and fixed before they become too serious. Problems can even be avoided before they present themselves. Still, misconceptions about the benefits of preventative maintenance regularly causes silo owners and operators to delay. Often times, unfortunately, by the time a problem surfaces, it may be so severe that it will take a large investment and a long period of time to resolve.

The payoff of preventative maintenance is all too apparent at those times. A Mole•Master™ customer recently experienced this first-hand. A cleanout project that initially would have been an easy and affordable job escalated quickly when the company delayed calling and attempted to fix it in-house without the right equipment. By the time Mole•Master™ was called in, the job required hundreds of thousands of dollars in time and effort not to mention significant and costly downtime.. A little preventative maintenance would have saved money and avoided down-time.

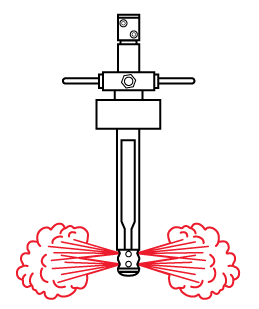

The key to preventative maintenance is regularly scheduled silo/bin/kiln cleaning. Regular cleanings mean that you can even “do it yourself.” Purchasing a Junior 360º™, Arch·Master™ or Safe-T-Shot™ system and adhering to safety guidelines can be enough to keep a silo, bin or kiln well maintained and free of problems. If handled immediately, these problems are typically able to be eliminated with plant personnel using equipment purchased or rented from Mole•Master™ or as a turnkey service. With either option chosen, the cost to clean early in the process will save valuable downtime and money.

Mole•Master’s proprietary Big•Mole™ Silo Cleaning Service ensures that all work will be completed safely and efficiently. Our techniques ensure that downtime will be minimized, a guarantee that cannot be offered if a problem is allowed to progress to emergency levels.

Pairing a preventative maintenance cleaning program with a professional silo inspection makes the most sense. The silo inspection will uncover any structural issues in both the interior and the exterior of the silo. A proper cleaning prior to the inspection will help the structural engineer identify any areas of concern from minor cracking to major catastrophic failure. Moreover, incorporating a silo inspection into the preventative maintenance plan helps ensure that all workers will be safe working around the structure and costly downtime will be avoided.